Pioneering Markforged 3D printer makes Australian debut

AIR Hub hosted the Victorian launch of the new printer at the Factory of the Future

In summary

- Swinburne’s Aerostructures Innovation Research Hub (AIR Hub) hosted the Australian launch of the Markforged FX20 printer

- This is Australia’s first openly accessible FX20

- Supporting nearly five times larger builds than previous models, the printer can maintain a temperature of up to 200°C to print flame-retardant, high-performance thermoplastic material

Australian manufacturers will gain access to a ground-breaking new composite 3D printer at Swinburne University of Technology, from global market leader Markforged, for the first time.

The Markforged FX20 printer is primarily designed for high-strength end-use parts in the aerospace, defence, automotive and energy industries. It prints nearly five times larger builds and is up to eight times faster than Markforged's existing line of composite printers.

It also features a heated build chamber capable of maintaining a temperature of up to 200°C to print flame-retardant, high-performance thermoplastic material.

Director of Swinburne’s Aerostructures Innovation Research Hub (AIR Hub) Dr Adriano Di Pietro said the state-of-the-art printer would be a game-changer for Australian businesses.

“AIR Hub is bringing industry together with cutting edge technology to support the growth of aviation and aerospace in Australia. We’re proud to be hosting Australia’s first openly accessible FX20 in Swinburne’s Factory of the Future.”

Building manufacturing capacity in Australia

This FX20 printer will be the first and only FX20 printer openly accessible to industry in Australia for use in research and development, helping promote new aerospace development and support the continued growth of the sector locally.

“The FX20 will strengthen local manufacturing capabilities and support reshoring across a wide range of sectors,” said Markforged Senior Director Australia, Richard Elving.

“Supply chain issues can be costly and time sensitive for Australian businesses. The FX20 will provide a competitive advantage to manufacturers by allowing them to react quickly to solve problems right on the manufacturing floor.”

AIR Hub hosted the Victorian launch of the new printer at the Factory of the Future on Tuesday 25 October as part of a three city launch tour in Melbourne, Perth and Sydney.

Speaking at the launch, Markforged CEO Shai Terem highlighted the ability of the FX20 to produce lightweight, advanced composite parts.

“With this combination of hardware and software, users can create end-use, mission critical parts and build resilient and sustainable supply chains that extend directly to the point-of-need.”

-

Media Enquiries

Related articles

-

- Astronomy

- Technology

- Science

- Engineering

Meet Swinburne’s Roo-ver Mission team

Roo-ver will be Australia's first lunar rover, and it’s being designed, built and tested in Australia. Swinburne is playing a key role in the design and construction of Roo-ver, through its involvement in the ELO2 Consortium.

Wednesday 26 November 2025 -

- Technology

- Health

- Science

- University

- Aviation

- Engineering

Swinburne’s Mobile Innovation Lab hits the road

Swinburne’s Mobile Innovation Lab is a cutting-edge mobile facility designed for research, industry collaboration, STEM education, training and outreach.

Thursday 06 November 2025 -

- Astronomy

- Technology

- Science

- Aviation

- Engineering

Shaping space innovation at the International Astronautical Congress

The 76th International Astronautical Congress (IAC) united over 7,000 delegates from more than 90 countries to explore the future of space. Swinburne staff and students delivered 20 talks, panels and presentations, showcasing Australia’s growing leadership in research and education.

Friday 10 October 2025 -

- Engineering

- Technology

- Aviation

Swinburne contributes to $270.5m Australian manufacturing research initiative

The Additive Manufacturing Cooperative Research Centre (AMCRC) seeks to transform Australia's healthcare, aerospace, and construction sectors.

Monday 28 April 2025 -

- Aviation

- Sustainability

- Engineering

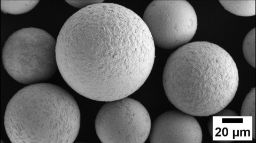

Australian-made sustainable powders to drive the future of advanced manufacturing

A high-tech spinout from Swinburne University of Technology will deliver Australian-made High Entropy Material (HEM) powders, developed from recycled industrial feedstocks, to advanced manufacturing and 3D printing facilities.

Thursday 27 March 2025