Radical disaster relief shelter design for Azraq and beyond

In Summary

- Dr Gregory Quinn is passionate about the needs of refugees when it comes to shelter and protection

- His SheltAir design takes inspiration from traditional Bedouin tents

- SheltAir’s curved gridshell structure offers a softer architectural approach

Dr Gregory Quinn is Discipline Coordinator for Architectural Engineering at the School of Design. For his doctoral thesis at Berlin University of the Arts, he developed a radical design for a disaster relief shelter.

Dr Quinn is passionate about the needs of refugees when it comes to shelter and protection from the elements and maintaining personal dignity. He refers to the Azraq refugee camp in Jordan with its challenging location, fluctuations in climate and long-term overcrowding. Azraq is home to 40,615 Syrian refugees.

His SheltAir design takes inspiration from traditional Bedouin tents, and makes use of advanced technology and pneumatic falsework (an inflatable cushion), for its erection.

Erecting the SheltAir prototype. Credit Gregory Quinn.

“SheltAir’s curved gridshell structure offers a softer architectural approach than box-like shelters. Shelters are emergency homes, but also places for emotional healing. The curved design of SheltAir has resonated well with Azraq camp residents,” explains Dr Quinn.

He has built a series of prototypes over four years to test SheltAir’s unique erection method, including the inflation itself; scope of possible shapes; architectural and structural design; and thermal performance. His custom computational methods simulate the erection process using a projection-based dynamic relaxation solver.

“The complex simulation involves large deformations, ‘collision’ between an inflating (initially deflated) bag and a compliant mechanism of rods with topological changes in the erection process,” he says.

A new application of ‘Kangaroo’ dynamic relaxation solver facilitated the erection simulation. Custom visualisation of internal forces, reactions and displacements were achieved via Python and C# scripts. Computational methods developed by Dr Quinn are being implemented in other areas including StructAR (augmented reality structures) – a novel interactive tool for learning structural engineering principles.

In 2017 Dr Quinn built a full-scale demonstrator of the SheltAir at ANCB Metropolitan Lab Berlin, as an exhibit and exhibition space. The construction took five days. In 2018 the build took three days and recently for an overhauled prototype built in collaboration with University of Bath, it took only eight hours to build the SheltAir. Dr Quinn is aiming for four hours with two people.

Full-scale SheltAir demonstrator at ANCB Metropolitan Lab Berlin 2017. Credit Gregory Quinn and Fabian Schneider.

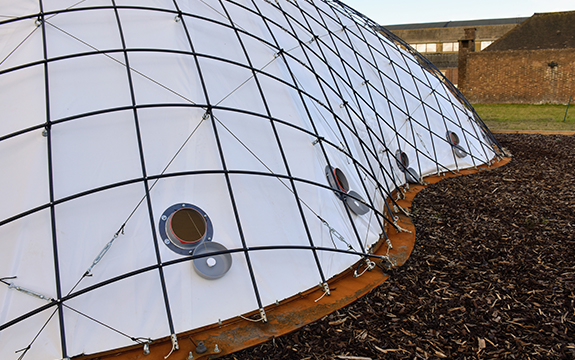

The latest version has a cushion made from PVC coated polyester fabric, glass fibre reinforced plastic rods pre-assembled in six segments and a perimeter foundation plate of 10mm laser cut Corten steel. When flat-packed it fits into two crates with six bundles of rods weighing close to one tonne. Further refinements are planned.

SheltAir with outer cover and gridshell. Credit Gregory Quinn.

Dr Quinn has experimented with reusing the inner cushion to erect multiple shelters. Currently the cushion remains inside to form the architectural envelope. There are versions with an outer cover that is dragged over the erected gridshell and anchored to foundation plates.

Credit Gregory Quinn.

Recent designs provide ventilation portholes and a central overhead opening to exploit the benefits of natural ventilation.

Recent designs feature ventilation portholes, overhead opening and curtain walls. Credit Gregory Quinn.

“As the architectural skin is on the inside and the gridshell on the outside, the gridshell can be used as a sacrificial formwork for insulation materials and additional membranes,” says Dr Quinn.

He says shelters aren’t always utilitarian and wider applications for SheltAir include a place for people to meet, pray, shelter and entertain.